Waste Plastic Pyrolysis Machine Pyrolysis Plastic To Fuel

Product description

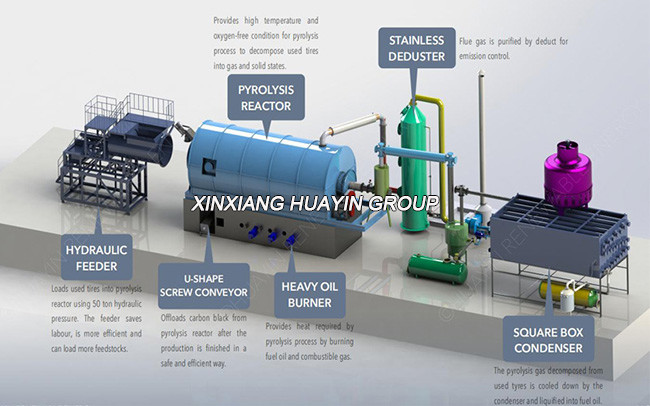

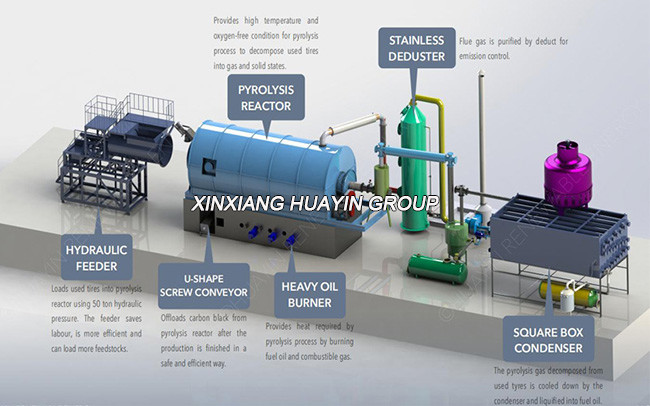

This set of plastic pyrolysis production line decomposes the

macromolecular polymer in waste plastic products thoroughly to

return it to the state of small molecules or monomers, and produces

pyrolysis oil, solid products and non-condensable combustible gas.

It is safe and environmentally friendly.

Usage of the output products

Fuel Oil (50%-75%)

1. Used as the heating material and sell it to cement factories,

glass factories, ceramic factories, electric power factories, steel

making factories, boiler factories, etc.

2. Used in heavy oil generator for electricity generation.

3. Deep process it into diesel oil with our distillation plant,

color and smell removal system, the final oil can be used in diesel

engines like trucks, tractors, etc.

Carbon Black (30%-35%)

Slag for construction.

Flammable Gas (8%-10%)

Recycled into the furnace to heat reactor instead of

coal/wood/oil/natural gas.

2. Storage the extra gas to restart the next batch.

Specification

| Item | Content |

| Raw materials | Waste tyre/rubber |

| Output | 45% fuel oil, 30% carbon black, 10% steel wire, 10%-15% syngas |

| Model | Reactor size | Capacity |

| HY1500*3000 | 1 T/batch |

| HY2000*4000 | 3T/batch |

| HY2200*6000 | 5 T/batch |

| HY2600*6000 | 7 T/batch |

| HY2600*6600 | 8 T/batch |

| HY2800*6000 | 9 T/batch |

| HY2800*6600 | 10 T/batch |

| HY2800*8100 | 15 T/batch |

| Reactor material and thickness | Q345R/Q245R/310S (Boiler plate/stainless steel) 14mm/16mm/18mm |

| The whole plant weight | 15-45 tons |

| Land area | 300-400m2(L30-40m*W10m) |

| Number of workers | 3-4 |

| Processing time and power | 10-24 hours. Averagely 15KW/h |

| Certification | CE, ISO, BV, SUV, SGS Oil Report, Emission Report, 11 patents |

Features of the waste plastic pyrolysis plant

Safety: Alarm, auto pressure releasing device, anti backfire device,

vacuum pump to ensure the machine working smoothly.

Oil-water separator: Its water sealing design ensures that oil and

gas are separated and combustible gas can not return to the

reactor.

Energy-saving:

The inner reactor body and outside insulation cover have good

airtightness, avoiding heating loss and saving fuel.

The combustible gas that cannot be further cooled down into fuel

oil will be recycled to the furnace for heating the reactor,

maximizing resource utilization.

The cooling water adopts a circulating mode, which is

pollution-free, no discharging, and recyclable.

High efficiency discharging: Adopt screw conveyor discharging device, discharge carbon black in

sealed condition, no pollution and save labor and time.

Fast installation: All of the condensing parts have been installed together before

delivery from the factory, saving installation time and ensuring

welding quality.

Auto feeder machine to feed raw material automatically, save labor and time.

Global cases

Oil ratio

| Raw materials | Oil ratio |

| PP (Microwave oven food box/yogurt bottles, ect.) | 50%-75% |

| PS(fast food boxes/instant noodle boxes) | 50%-75% |

| PE(plastic film/plastic wrap) | 50%-75% |

| Plastic cable | 80% |

| ABS(engineering plastic) | 40% |

| Leftovers of paper | Wet 15-20%,Dry 60% |

| House garbage | 35%-50% |

| Plastic bags | 50% |

| Submarine cable | 75% |

| Rubber cable | 35% |

| Sole | 30% |

| Small tires | 45%-50% |